Moderniausia įranga, teikianti tikslias lakštinio metalo ir plieno profilių pjovimo paslaugas

Produkto informacija

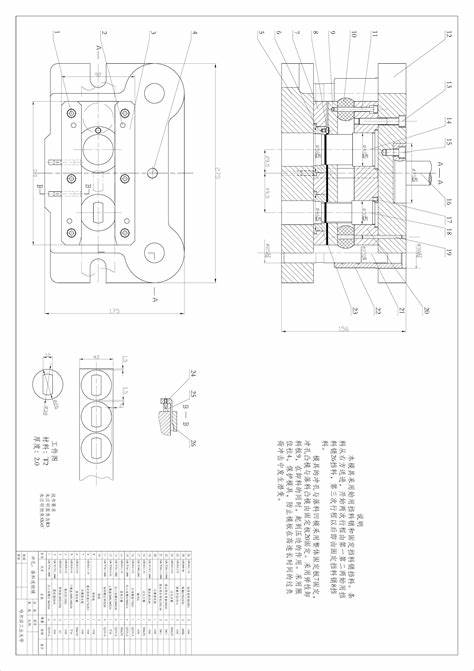

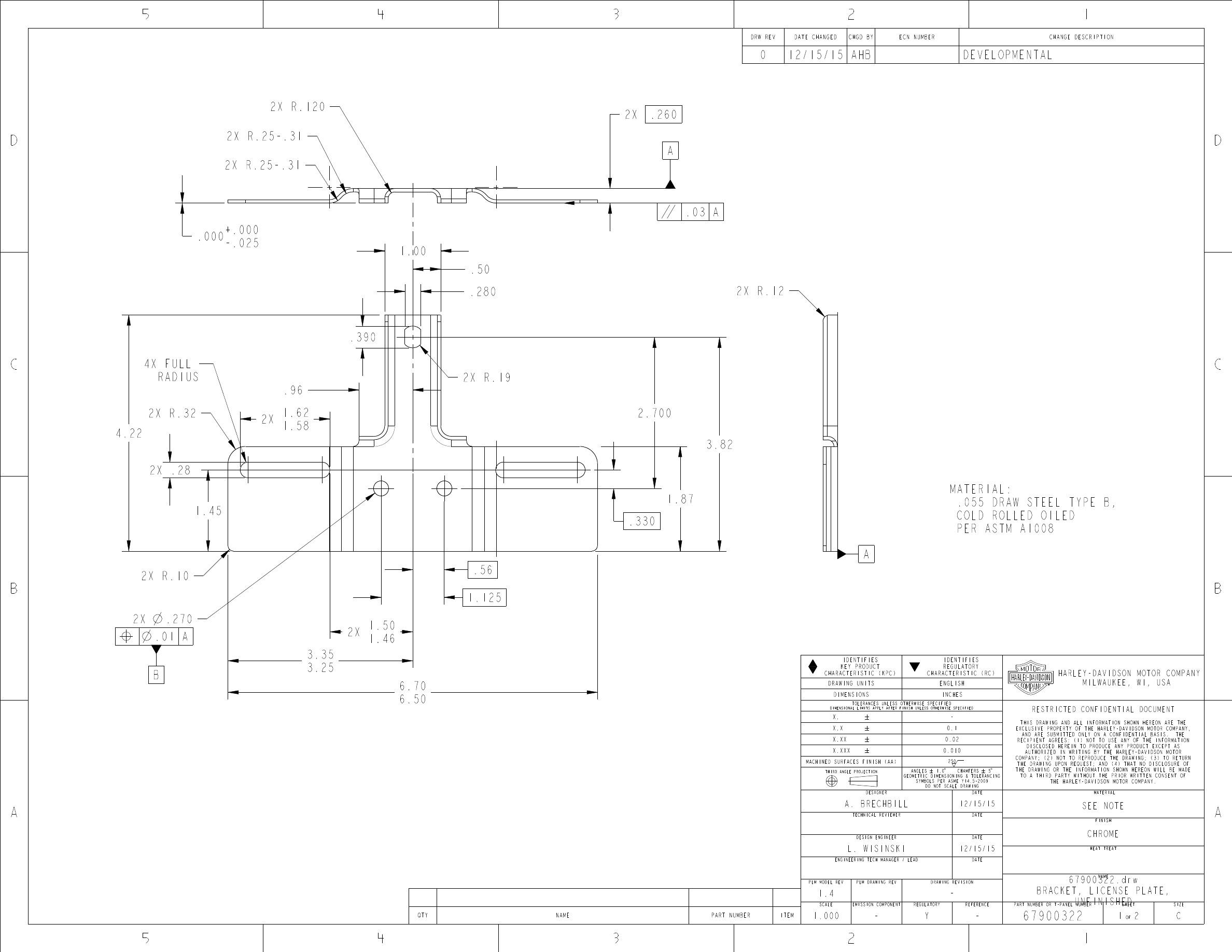

Plieno apdirbamos detalės gaminamos iš plieno žaliavų, pagal klientų pateiktus gaminių brėžinius, pagal individualias ir pritaikytas gaminių gamybos formas pagal reikiamas gaminių specifikacijas, matmenis, medžiagas, specialų paviršiaus apdorojimą ir kitą apdorojamų detalių informaciją. Tiksli, aukštos kokybės ir aukštųjų technologijų gamyba atliekama pagal klientų reikalavimus. Jei nėra projekto brėžinių, tai gerai. Mūsų gaminių konstruktoriai suprojektuos pagal kliento poreikius.

Pagrindiniai apdirbamų dalių tipai:

suvirintos detalės, perforuoti gaminiai, dengtos detalės, lenktos detalės,lakštinio metalo pjovimas

lazeriu pjaustytas lakštinis metalaspasižymi šiomis savybėmis: pirma, jis turi platų pritaikymo spektrą ir gali pjauti įvairias medžiagas, tokias kaip metalai, nemetalai ir kompozicinės medžiagos, nesudarant karščio paveiktų zonų ir gedimo zonų. Jis tinka tiksliam įvairių medžiagų apdirbimui. Antra, pjovimo procese nereikia naudoti cheminių medžiagų, jis yra ekologiškas, netoksiškas ir nekenksmingas, atitinka šiuolaikinės gamybos žaliosios aplinkos apsaugos reikalavimus. Be to, pjovimas vandens srove gali pasiekti didelio tikslumo, aukštos kokybės pjovimą su lygiais pjovimo paviršiais be antrinio apdorojimo poreikio, taupant gamybos sąnaudas.

Vandens srovės pjovimas plačiai naudojamas aviacijos ir kosmoso, automobilių gamybos, statybinių medžiagų ir kitose srityse. Aviacijos ir kosmoso srityje vandens srovės pjovimas gali būti naudojamas orlaivių dalims, tokioms kaip fiuzeliažas, sparnai ir kt., pjauti, užtikrinant detalių tikslumą ir kokybę. Automobilių gamyboje vandens srovės pjovimas gali būti naudojamas kėbulo plokštėms, važiuoklės dalims ir kt. pjauti, užtikrinant detalių tikslumą ir išvaizdos kokybę. Statybinių medžiagų srityje vandens srovės pjovimas gali būti naudojamas marmurui, granitui ir kitoms medžiagoms pjauti, siekiant tikslaus drožinio ir pjovimo.

Trumpai tariant, vandens srovės pjovimas, kaip efektyvi, ekologiška ir didelio tikslumo pjovimo bei apdorojimo technologija, turi plačias taikymo perspektyvas ir rinkos paklausą, todėl atliks svarbų vaidmenį būsimoje gamybos pramonėje.

| Pasirinktinisminkšto plieno pjovimasTikslios lakštinio metalo gamybos dalys | ||||

| Citata | Pagal jūsų brėžinį (dydį, medžiagą, storį, apdorojimo turinį ir reikiamą technologiją ir kt.) | |||

| Medžiaga | Anglinis plienas, nerūdijantis plienas, SPCc, SGCc, vamzdis, cinkuotas | |||

| Apdorojimas | Lazerinis pjovimas, lenkimas, kniedėmis jungimas, gręžimas, suvirinimas, lakštinio metalo formavimas, surinkimas ir kt. | |||

| Paviršiaus apdorojimas | Šepetys, poliravimas, anodavimas, miltelinis dažymas, dengimas, | |||

| Tolerancija | '+/- 0,2 mm, 100% kokybės kontrolė prieš pristatymą, gali pateikti kokybės patikrinimo formą | |||

| Logotipas | Šilkografija, lazerinis žymėjimas | |||

| Dydis/Spalva | Priima pasirinktinius dydžius / spalvas | |||

| Piešimo formatas | .DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.Juodraštis | |||

| Mėginio valgymo laikas | Derykitės dėl pristatymo laiko pagal savo poreikius | |||

| Pakavimas | Pagal dėžutę / dėžę arba pagal jūsų reikalavimą | |||

| sertifikatas | ISO9001: SGS/TUV/ROHS | |||

Pateikite pavyzdį

| Individualiai apdirbtos dalys | |

| 1. Dydis | Individualus |

| 2. Standartas: | Individualus arba GB |

| 3. Medžiaga | Individualus |

| 4. Mūsų gamyklos vieta | Tiandzine, Kinijoje |

| 5. Naudojimas: | Patenkinti klientų poreikius |

| 6. Danga: | Individualus |

| 7. Technika: | Individualus |

| 8. Tipas: | Individualus |

| 9. Skyriaus forma: | Individualus |

| 10. Patikrinimas: | Kliento arba trečiosios šalies atliekama apžiūra. |

| 11. Pristatymas: | Konteineris, birus laivas. |

| 12. Apie mūsų kokybę: | 1) Be pažeidimų, be sulenkimų 2) Tikslūs matmenys 3) Visas prekes prieš išsiuntimą gali patikrinti trečioji šalis |

Kalbant apie metalo pjovimą, yra keletas metodų, kuriuos galima naudoti, priklausomai nuo metalo rūšies ir norimo rezultato. Kai kurie iš labiausiai paplitusių pjovimo procesų yra lazerinis pjovimas, plazminis pjovimas, vandens srovės pjovimas ir kirpimas. Lazerinis pjovimas idealiai tinka tiksliems ir sudėtingiems pjūviams atlikti, o plazminis pjovimas geriausiai tinka pjauti storus metalo lakštus. Pjaustymas vandens srove yra universalus variantas, leidžiantis pjauti įvairias medžiagas, o kirpimas yra ekonomiškas būdas pjauti tiesias linijas ant lakštinio metalo.

Renkantis metalo pjovimo paslaugą, svarbu atsižvelgti į konkrečius jūsų projekto reikalavimus. Nesvarbu, ar jums reikia...pjaustytas plieno lakštas, minkšto plieno ar kitų rūšių metalo, ieškokite paslaugų teikėjo, turinčio reikiamos patirties ir įrangos, kad patenkintų jūsų konkrečius poreikius. Atsižvelkite į tokius veiksnius kaip metalo storis, pjūvių sudėtingumas ir pageidaujama pjūvių briaunų apdaila.

Be to, svarbu pasirinktimetalo pjovimo paslaugoskuri teikia pirmenybę tikslumui, kokybei ir efektyvumui. Ieškokite tiekėjo, kuris naudoja pažangias pjovimo technologijas ir turi aukštos kokybės rezultatų teikimo patirtį. Taip pat naudinga rinktis paslaugą, kuri siūlo papildomas paslaugas, tokias kaip metalo apdirbimas, apdaila ir surinkimas, siekiant supaprastinti gamybos procesą ir užtikrinti sklandų sprendimą nuo pradžios iki pabaigos.

Gatavo produkto demonstravimas

Pakuotė ir siuntimas

Vandens srove pjaustomų detalių pakavimas ir transportavimas yra svarbi gaminio kokybės ir saugaus pristatymo užtikrinimo dalis. Visų pirma, vandens srove pjaustomoms detalėms, dėl jų lygaus pjovimo paviršiaus ir didelio tikslumo, būtina pasirinkti tinkamas pakavimo medžiagas ir būdus, kad būtų išvengta pažeidimų transportavimo metu. Mažoms...metalo lazerinio pjovimo paslauga, juos galima supakuoti į putplasčio dėžes arba kartonines dėžes. Didelės vandens srove pjaustomos dalys paprastai turi būti supakuotos į medines dėžes, kad transportavimo metu nebūtų pažeistos.

Pakavimo proceso metu vandens srove pjaustomos dalys turėtų būti tinkamai pritvirtintos ir užpildytos atsižvelgiant į vandens srove pjaustomų dalių charakteristikas, kad transportavimo metu nebūtų pažeistos dėl susidūrimo ir vibracijos. Specialių formų vandens srove pjaustomoms dalims taip pat reikia suprojektuoti individualius pakavimo sprendimus, užtikrinančius jų stabilumą transportavimo metu.

Transportavimo proceso metu reikėtų pasirinkti patikimą logistikos partnerį, siekiant užtikrinti, kad vandens srove pjaustomos detalės būtų saugiai ir laiku pristatytos į paskirties vietą. Tarptautiniams gabenimams taip pat reikia suprasti atitinkamus paskirties šalies importo reglamentus ir transportavimo standartus, kad būtų užtikrintas sklandus muitinės formalumų atlikimas ir pristatymas.

Be to, kai kurioms vandens srove pjaustomoms detalėms, pagamintoms iš specialių medžiagų arba sudėtingų formų, pakavimo ir transportavimo metu reikia atkreipti dėmesį į specialius reikalavimus, tokius kaip atsparumas drėgmei ir korozijai, kad nebūtų paveikta produkto kokybė.

Apibendrinant galima teigti, kad vandens srove pjaustomų detalių pakavimas ir transportavimas yra svarbios grandys, užtikrinančios produkto kokybę ir klientų pasitenkinimą. Norint užtikrinti produkto saugą ir vientisumą bei pristatymą klientams laiku, reikia atlikti pagrįstą planavimą ir operacijas, susijusias su pakavimo medžiagų pasirinkimu, fiksuotu užpildymu, transportavimo parinkimu ir kt.

ĮMONĖS STIPRYBĖ

Pagaminta Kinijoje, aukščiausios klasės aptarnavimas, pažangiausia kokybė, visame pasaulyje žinomas

1. Masto efektas: Mūsų įmonė turi didelę tiekimo grandinę ir didelę plieno gamyklą, todėl pasiekia masto efektų transporto ir pirkimų srityse ir tampa plieno įmone, integruojančia gamybą ir paslaugas.

2. Produktų įvairovė: Produktų įvairovė, bet kokį norimą plieną galite įsigyti iš mūsų, daugiausia užsiimame plieninėmis konstrukcijomis, plieniniais bėgiais, plieniniais lakštiniais poliais, fotovoltiniais laikikliais, kanaliniu plienu, silicio plieno ritiniais ir kitais gaminiais, todėl jis yra lankstesnis. Pasirinkite norimą gaminio tipą, kad patenkintumėte skirtingus poreikius.

3. Stabilus tiekimas: stabilesnė gamybos linija ir tiekimo grandinė gali užtikrinti patikimesnį tiekimą. Tai ypač svarbu pirkėjams, kuriems reikia didelių plieno kiekių.

4. Prekės ženklo įtaka: didesnė prekės ženklo įtaka ir didesnė rinka

5. Aptarnavimas: didelė plieno įmonė, integruojanti pritaikymą, transportavimą ir gamybą

6. Kainų konkurencingumas: priimtina kaina

KLIENTAI APSILANKO

DUK

1.Kaip gauti iš jūsų citatą?

Galite palikti mums žinutę ir mes laiku atsakysime į kiekvieną žinutę.

2. Ar pristatysite prekes laiku?

Taip, pažadame teikti aukščiausios kokybės produktus ir pristatyti juos laiku. Sąžiningumas yra mūsų įmonės principas.

3. Ar galiu gauti pavyzdžių prieš užsakymą?

Taip, žinoma. Paprastai mūsų pavyzdžiai yra nemokami, galime pagaminti pagal jūsų pavyzdžius arba techninius brėžinius.

4. Kokios yra jūsų mokėjimo sąlygos?

Įprastas mūsų mokėjimo terminas yra 30% užstatas, o likusi dalis – važtaraštis.

5. Ar sutinkate su trečiosios šalies patikrinimu?

Taip, be jokios abejonės, priimame.

6. Kaip mes pasitikime jūsų įmone?

Mes specializuojamės plieno versle jau daugelį metų kaip auksinis tiekėjas, mūsų būstinė yra Tiandzino provincijoje, todėl kviečiame bet kokiu būdu ir bet kokiomis priemonėmis ištirti.